Driving Question:

How can you use traditional Bosnian carpentry techniques to create innovative product designs?

Module Summary:

The “Carpentry and Innovation” module, tasked students with transforming a plank of wood into an innovative and culturally significant piece over five days. Working closely with local experts in Konjic, the students learned traditional Bosnian carving techniques. They designed and created wooden carvings and objects, using both sketches and 3D models.

Students visited the Zanat factory and a wood carving museum, where they were introduced to different types of wood, carpentry, and woodworking techniques. They also delved into the innovation aspect, learning about the difference between innovation and invention, legal and ethical considerations, and the process of idea protection through patents, trade secrets, and copyrights.

After mastering the basics, the students created their final products in two factory spaces: Elektra, where they worked on sawing, chiseling, and filing their basic shapes, and Zanat, where they refined their shapes, added intricate patterns, and completed their projects with sanding and oiling.

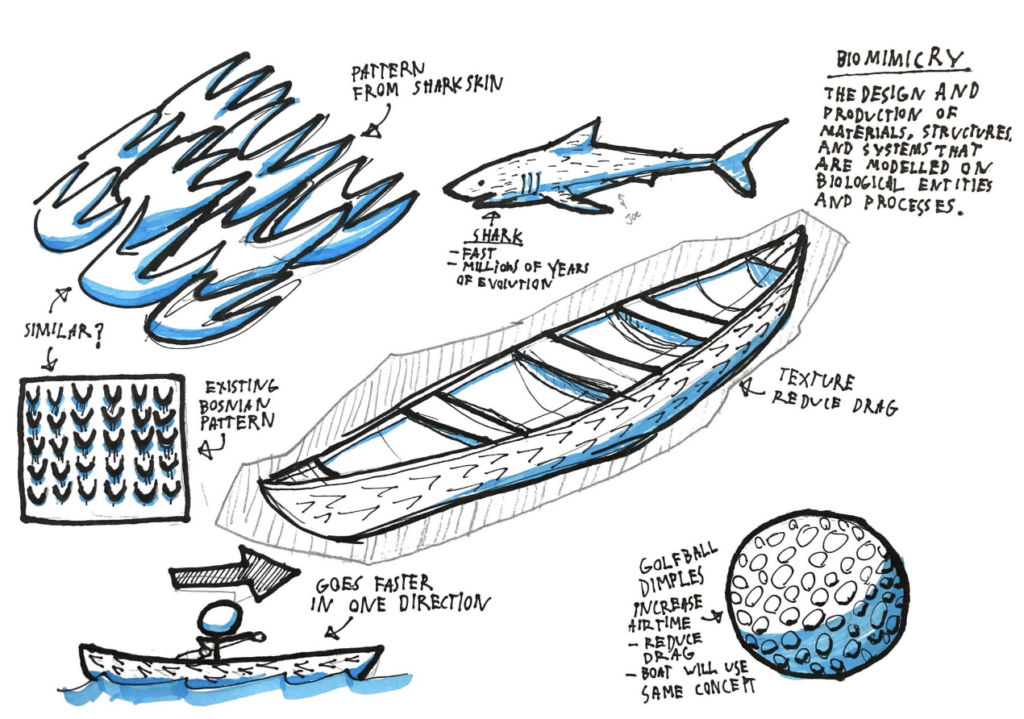

Niko W.’s final product is an oak wooden boat with a unique texture designed to enhance its hydrodynamic performance, akin to the dimples on a golf ball or sharkskin texture. He employed two types of chiseling techniques—flat-headed, curved, and V-shaped—to serve different purposes in crafting the boat. The rip saw, while providing a cleaner cut, required more time compared to the bow saw, which removed more material but left a rougher finish.

Initially using the rip saw for shaping, Niko later switched to the bow saw based on feedback from Alestra staff, prioritizing time efficiency over surface smoothness, as he planned to refine the boat’s sides through subsequent shaping and sanding. To achieve smoother edges and surfaces, he utilized a file initially for its material-removal capability, followed by 80-grit sandpaper to refine the texture further.